EMIcare Field Service and Training of Roundness and Surface Roughness Instruments

Having years of experience working with surface roughness and roundness metrology equipment has enabled us to become experts in repair as well as applications. When it comes to preventative maintenance, calibration or repair of surface roughness and roundness measuring instruments, EMI Gage is capable of providing you with independent ongoing support and service at reasonable rates.

Field Service Repair

and

Calibration for Roundness and Surface Roughness Instruments

- Field Engineers based in North Carolina, Ohio, Tennessee and Illinois. Spare Parts Network for obtaining obsolete and difficult to find parts.

- Repair of all models of surface texture, form and roundness instruments.

- Experienced metrology experts providing all levels of training and consulting pertaining to surface texture, form and roundness.

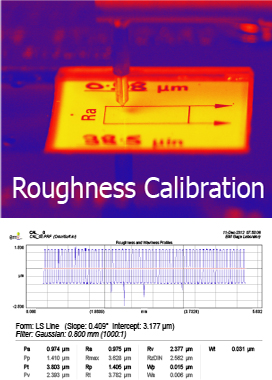

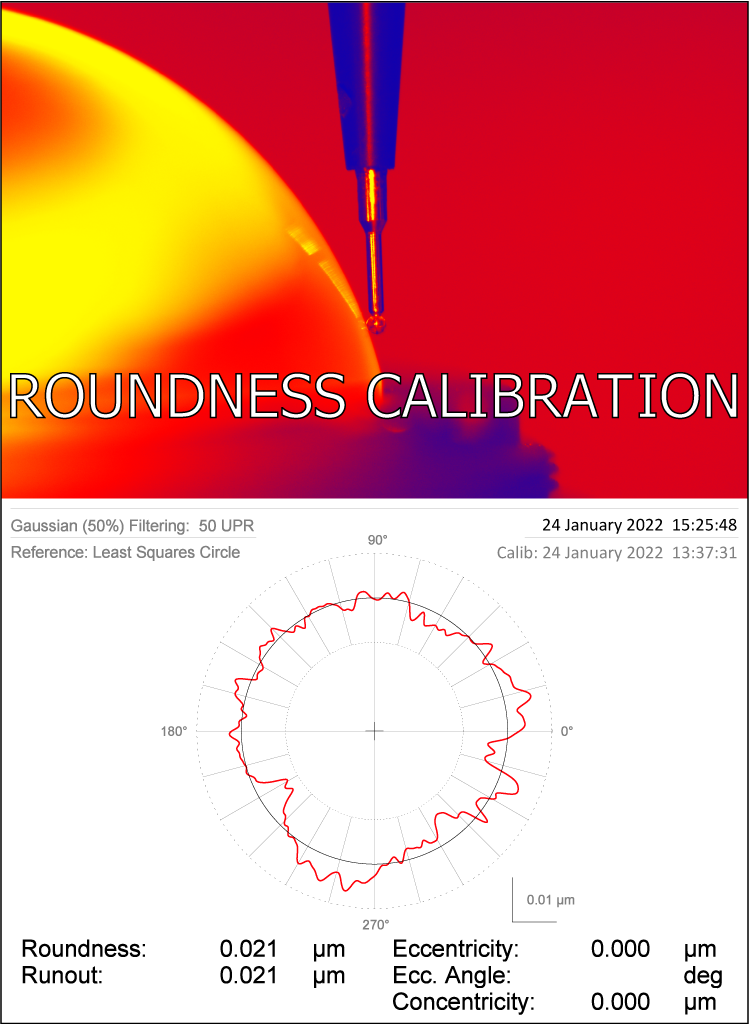

- Independent calibration service, providing traceablility to N.I.S.T. for all surface texture and roundness gages.

- Correlation studies and third party inspections for OEM's, subcontractors and designers.

We realize that turnaround on repairs is of the utmost importance to our customers. It is our goal to meet any reasonable turnaround request we receive - why not try us?

We provide complete surface roughness and roundness stylus repair. We have two, five and ten micron diamond tips in stock (special tips upon request). Testing of diamonds and replacements. Ruby ball tip replacements for roundness and contour styli. Stylus repair and manufacturing is a large portion of our business and therefore stylus parts are on hand at all times. We provide rapid turnaround of repairs and new styli - we can manufacture custom roundness and surface roughness styli for all major OEM manufacturers.

Surface roughness and roundness pickup probe repair. EMI Gage has designed its own custom test stands providing repair capabilities for pickups (commonly referred as probes and transducers), including Taylor Hobson Talysurf 4,5,6 and 10™*. Taylor Hobson Form Talysurf Series™* LASER and Inductive pickups, "Talyrond"™* and "Surtronic"™* pickups.