EMI GAGE LABORATORY

Surface Roughness, Form and Geometry Measurement Services

|

EMI GAGE LABORATORYSurface Roughness, Form and Geometry Measurement Services |

|

|---|

EMI Gage Laboratory not only provides support for our manufacturing capabilities but it also provides support for many of our clients.

Based in Lake Barrington, Illinois, we provide calibration services for artifacts and instruments throughout the USA and worldwide.

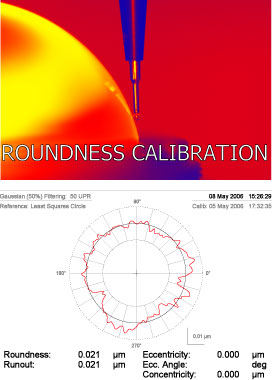

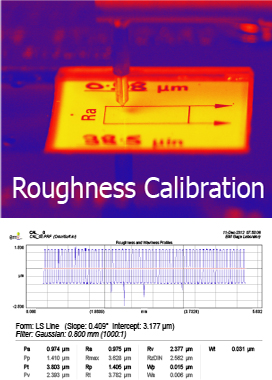

We can calibrate roughness standards for Ra (roughness average) and Rz (maximum peak to valley height within a sampling length) parameters. We can also calibrate roundness artifacts (Hemisphere/Flick). All calibrated artifacts are traceable to ISO/IEC 17025:2017.

In addition to a well-equipped lab, our staff has many years of metrology training and experience. Having worked on so many different applications, we have the broad base of contacts and experience necessary to solve most Surface Texture and Roundness metrology problems.

The heart of our laboratory is the Liebert Challenger 3000. This climate control unit maintains the temperature and humidity within a very tight bandwidth. Temperature is kept at 68º F plus or minus 0.5 degrees F. Humidity is kept at 30% Relative Humidity (RH). A large HEPA filter array can hold the lab cleanliness to better than Class 10,000.

| Surface Texture | Roundness | Miscellaneous |

|---|---|---|

Taylor Hobson PGI 1230 Laser / 700mm Column |

Taylor Hobson Talyrond 262 750mm Column |

Nikon Profile Projector |

Taylor Hobson S5 Laser / 700mm Column |

Taylor Hobson Talyrond 265 500mm Column |

Nikon Digital Microscopy |

| Taylor Hobson S4C Inductive/ 450mm Column | Pneumo Large Bearing Spindle 30" | Newport Linear/Rotary Stages/Custom Fixturing |

TH Surtronic, TSK Handysurf, MTI Surftest and Mahr Portable Instruments |

Mahr MMQ100 | Mahr/TESA Handtools |

Are you looking to have some of your sample parts inspected for roughness, form,

roundness or cylindricity? Do you have correlation problems with your

customer/supplier? Are you qualifying a machine tool for production? EMI

Gage Laboratory may have a suitable solution for your needs.

EMI Gage specializes in surface texture measurement, form (profile measurement), and roundness (roundness, straightness, cylindricity, runout, harmonics, parallelism etc.) metrology. We bring many years of knowledge and expertise to your most demanding applications and help you find the solution to your pressing problems.

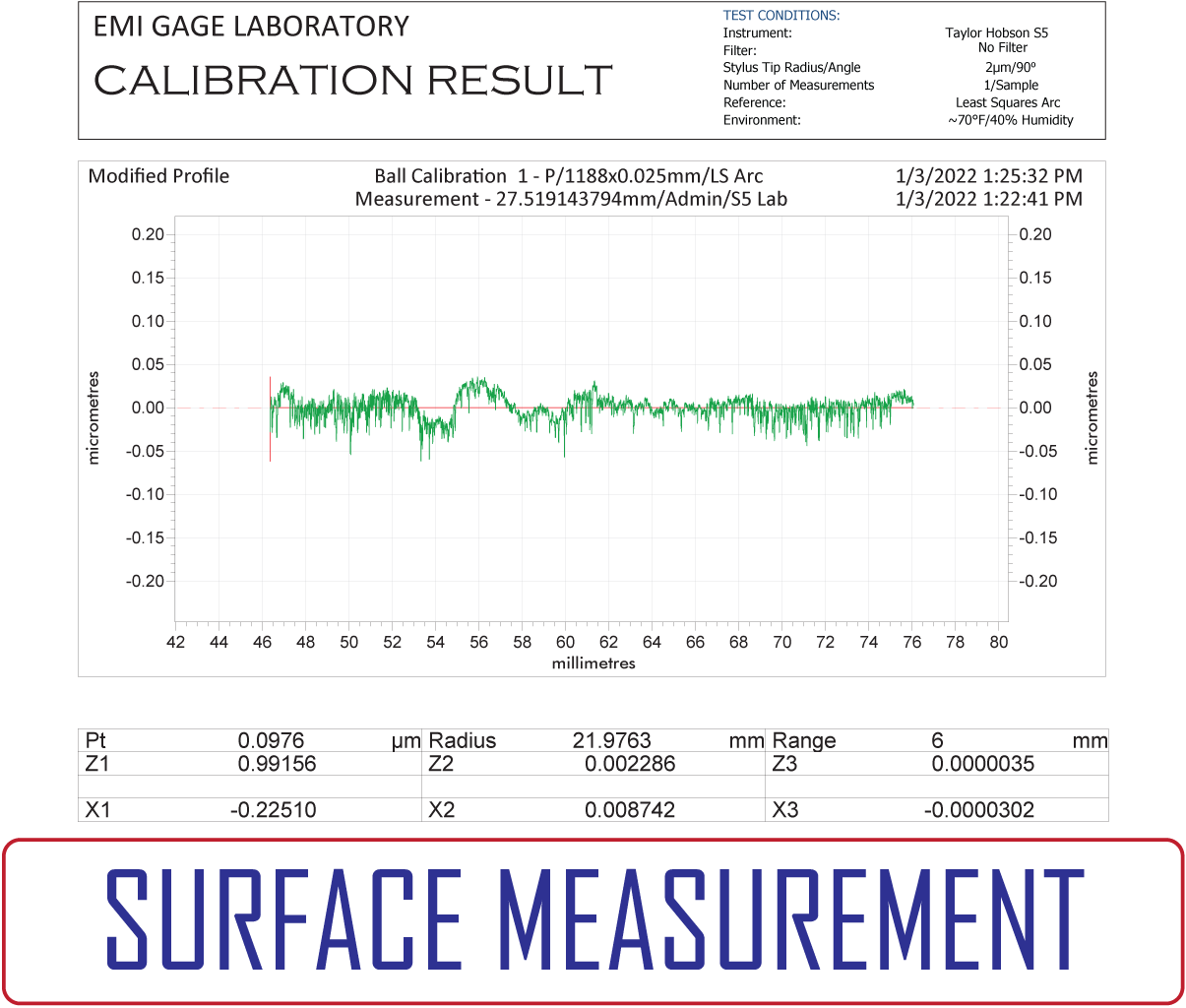

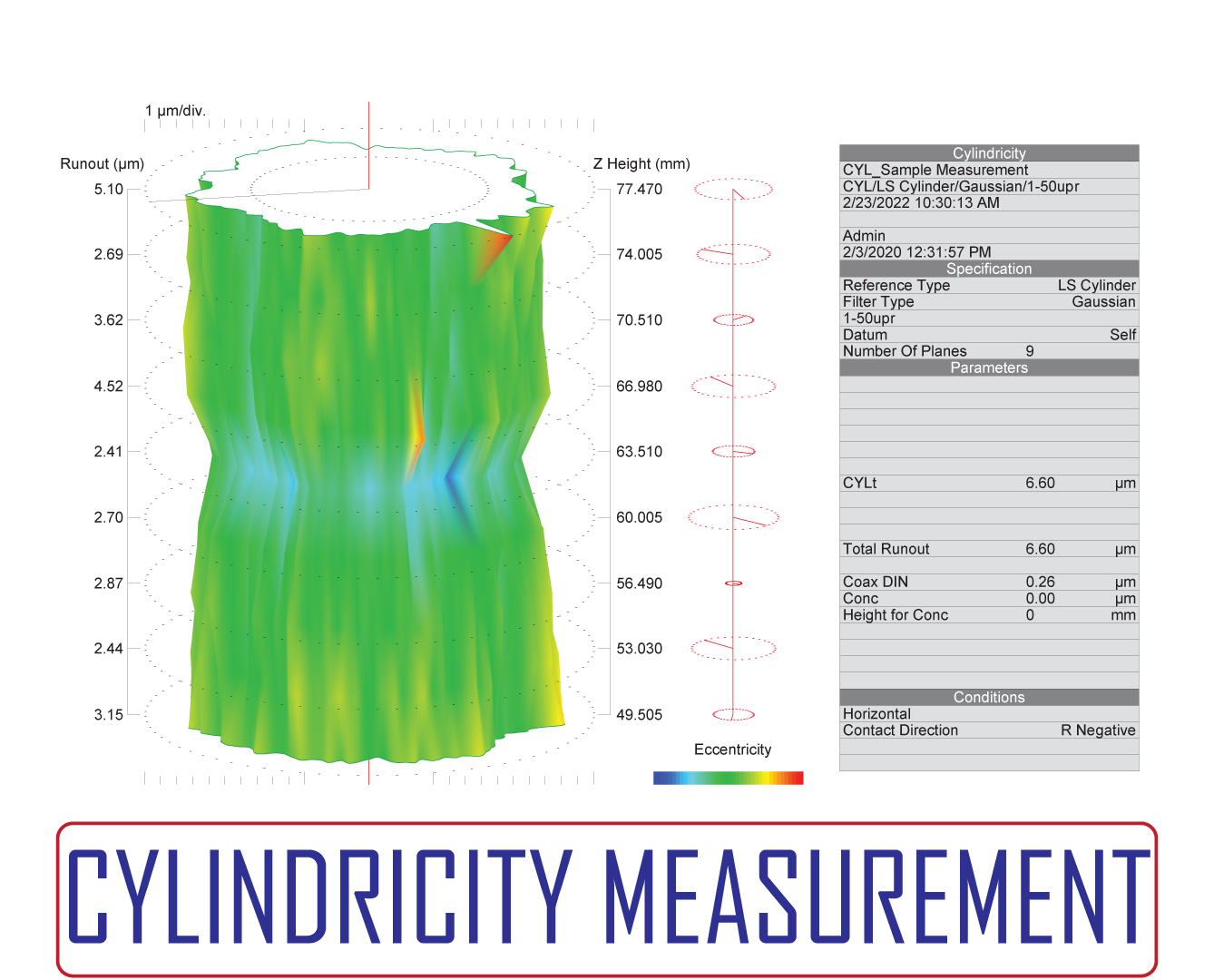

In order to provide the highest quality service, we have focused on one method: Tracing the peaks and valleys of a surface by contact probing in order to evaluate any variations from the desired shape. In specializing our inspection to a single method, we have developed a broad base of highly specialized knowledge. This expertise in surface texture and form metrology allows us to add value to your part inspection needs. We feature renowned Taylor Hobson surface texture and roundness geometry measuring systems in our laboratory. We have full capability of: surface roughness measurement, waviness measurement, form measurement, radius measurement, roundness measurement, straightness measurement, parallelism measurement, concentricity measurement, runout measurement, squareness measurement, cylindricity measurement, harmonics and flatness measurement. |

||

|

|

|

| Surface Roughness and Form Inspection with both inductive and laser drive units ensure maximum range and resolution. | Precision measurement of Roundness, Straightness, Cylindricity, Concentricity, Eccentricity, Flatness, Squareness (Perpendicularity), Parallelism, Coaxiality, Runout and Harmonics. |

Medical - Artificial joint surface texture and form features. Dental R&D, Surface texture of surgical instruments.

Food Service - Surface texture of food service equipment.

Automotive/Aerospace/Stamping - Used extensively anywhere surface texture is a concern. i.e. bearing race, cylinder wall, fuel injectors. Radius measurement of internal and external partial arcs.

Machine Tool Mfg. - Run-offs for precision manufacturing equipment. Machine qualification and process improvement.

Defense Industry- Used by the Air Force and other branches to check aircraft and defense parts.

Optics - Measurement of contact lens mold radius. Full aspheric and conic lens analysis capabilities.

We can calibrate roughness standards for Ra (roughness average) and Rz (maximum peak to valley height within a sampling length) parameters. We can also calibrate roundness artifacts (Hemisphere/Flick).All artifacts are traceable to ISO/IEC17025:2005.

|

|

|

|

| View Certification (pdf format) | Quality Policy Statement |

|

|