How bad is “too bad?”

Replacing a metrology system can be a huge expense, so keeping older gages in service is vital for many businesses. Older systems need support to keep going, but even instruments with a lot of wear and tear can continue to perform reliably.

So, how bad can a system get, but still be useable?

It just needs calibration and cleaning…

Gage manufacturers typically offer basic calibration services, applying correction factors so that the gage continues to read valid numbers…

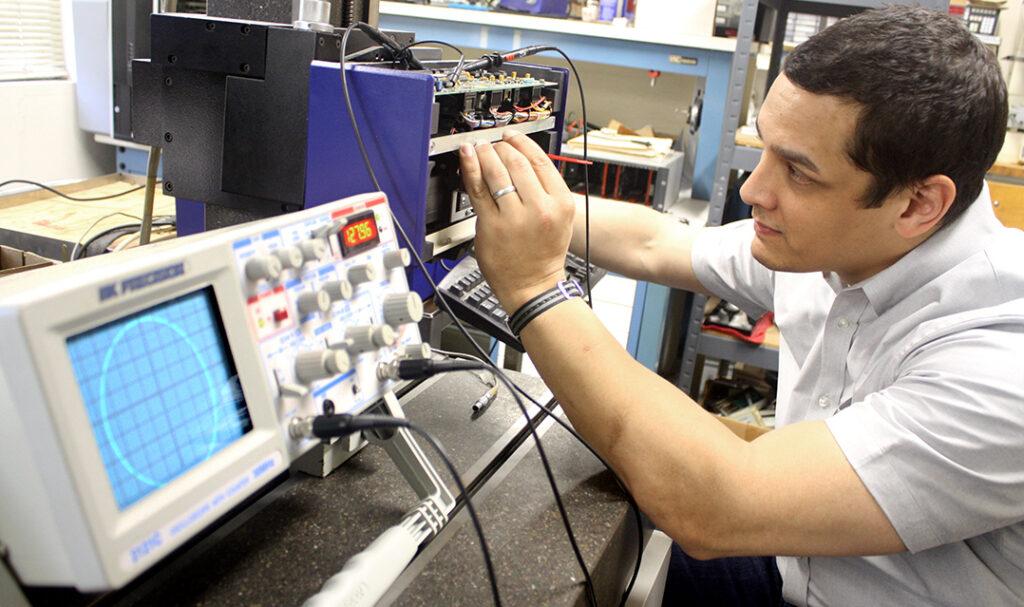

…but let’s check the whole system

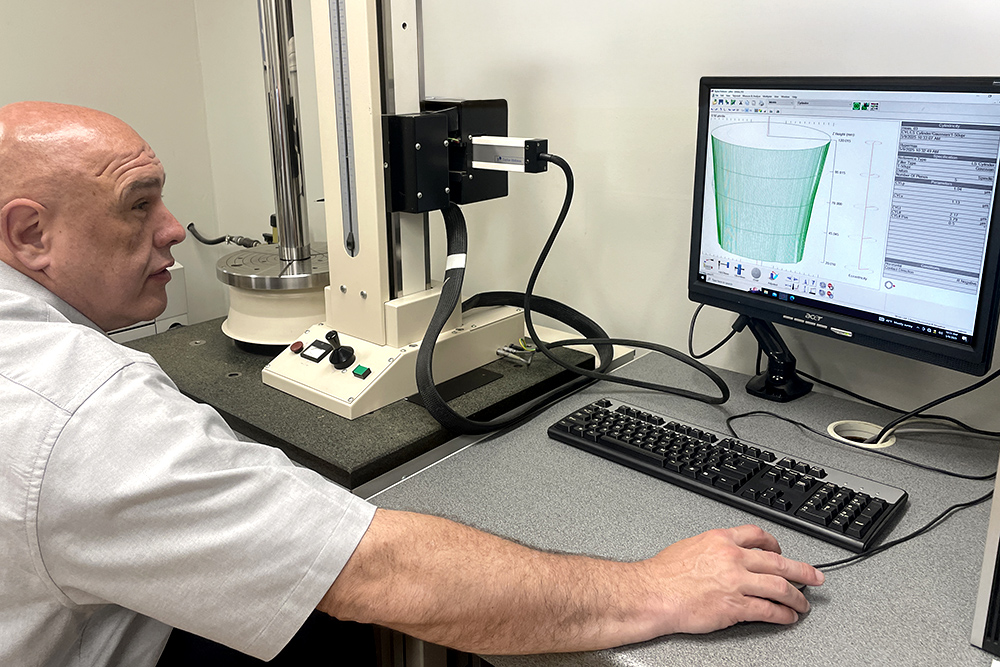

The issue with basic calibration is that the gage is only “calibrated” for the specific conditions when the corrections are applied. If the datum isn’t straight, if there’s contamination in the system, etc., then measurements made over other portions of the gage’s range may very well be unreliable, even though the instrument has a calibration sticker.

To that end, our technicians always check the entire system during a visit. That may include cleaning the system and making minor (sometimes major) corrections on site, so that the gage performs over its entire range and is back in service immediately.

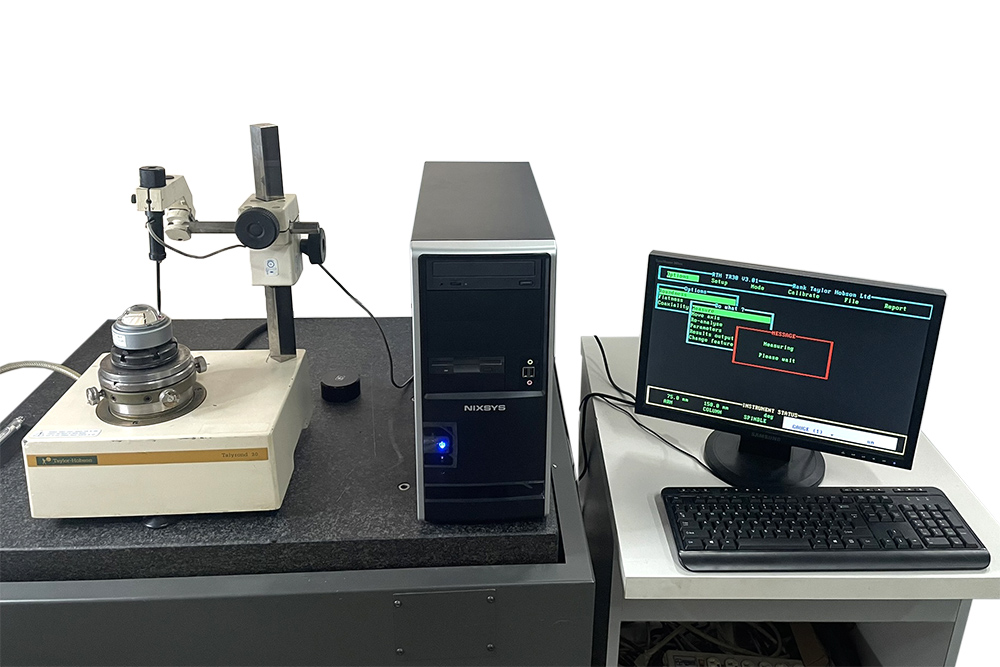

The gage is fine, but the computer isn’t supported

Perfectly good measurement systems are regularly scrapped simply because the computer or operating system is no longer supported by the manufacturer. To us, this seems like an incredible waste of resource. We are able to source computers running legacy operating systems all the way back to DOS to keep older gages in service, for a tiny fraction of the cost to replace a gage and to retrain staff to use it.

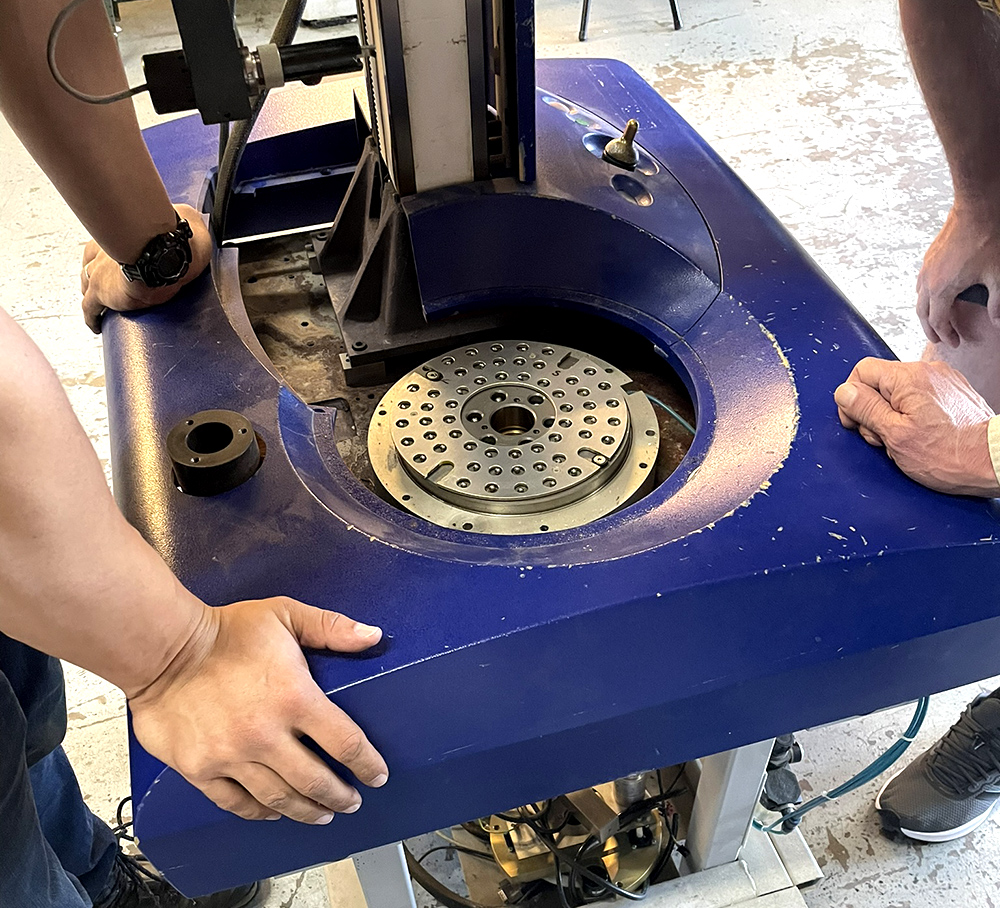

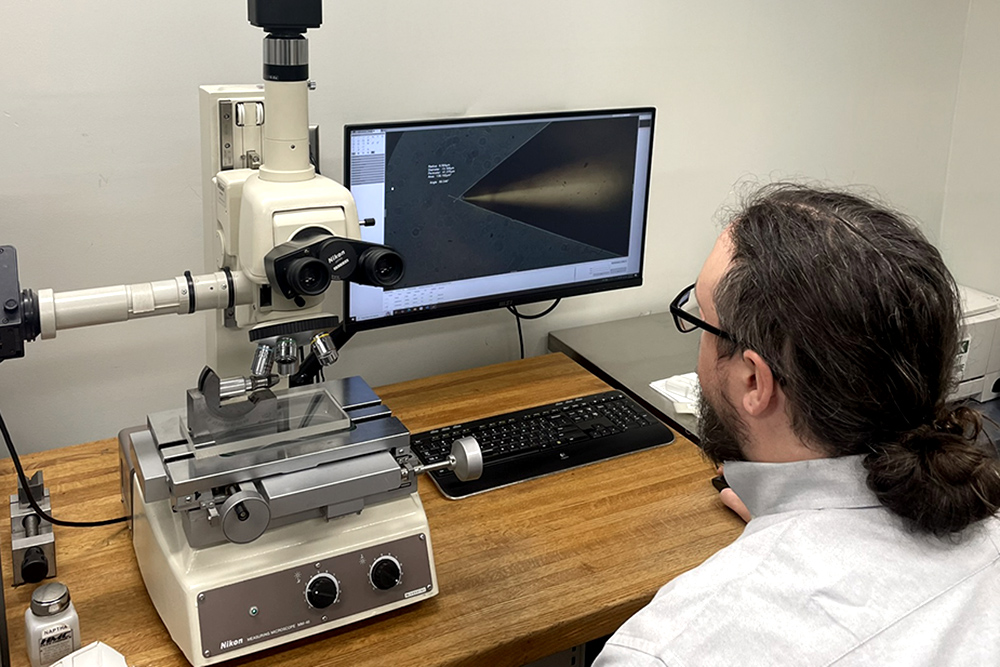

More extensive repairs

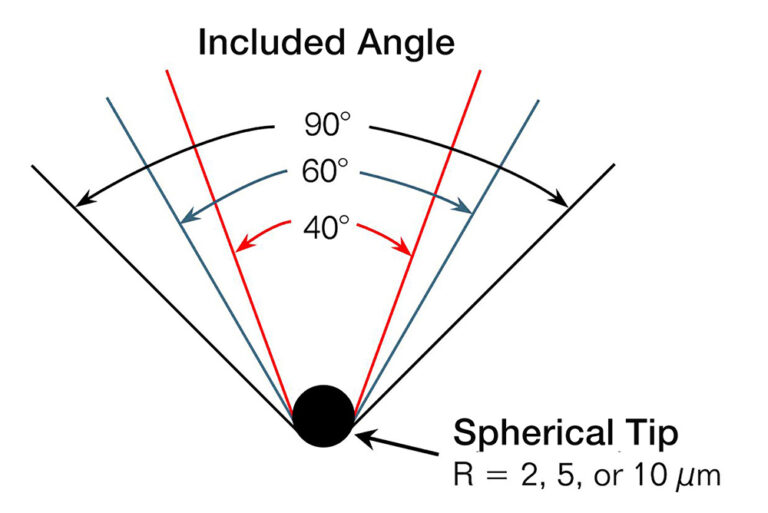

If a critical issue is discovered during a routine visit, we can transport a gage back to our shop for more thorough repairs in controlled conditions. Our shop is equipped to tear a machine down to the nuts and bolts to verify and repair every system. From replacing a diamond tip to repairing an air bearing, we can guarantee your gage will function for years to come.

So…how bad is too bad?

EMI Gage has been able to repair dozens of distressed systems, at a fraction of the cost of replacement. If the basic structure can be salvaged, we can probably fix it.

Got a system that needs calibration, cleaning, repair, or more? Contact us for a review and free estimate.