In-House Services

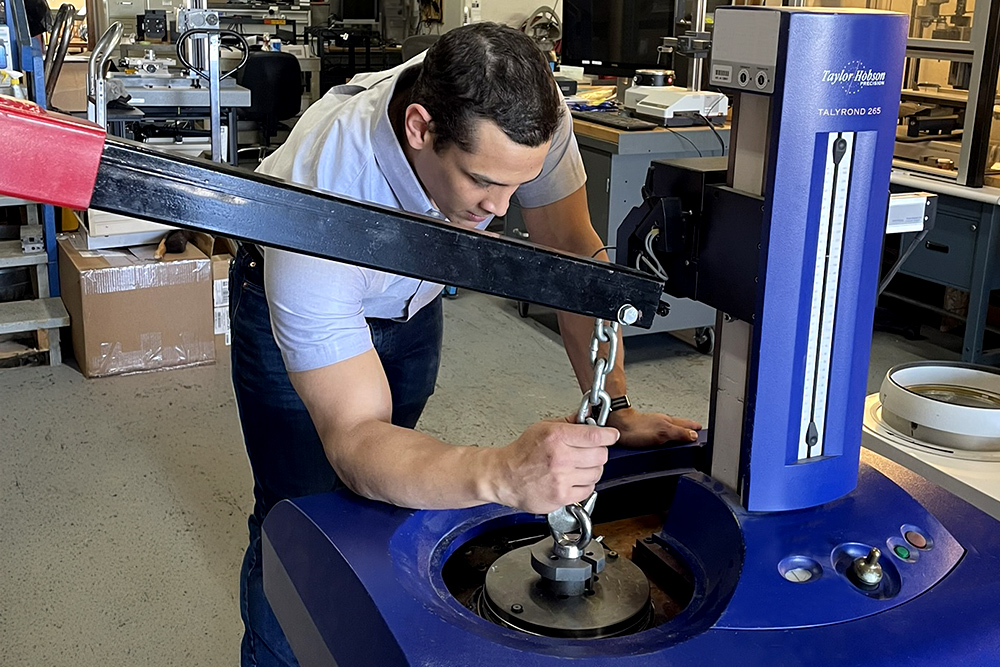

Gage Repair and Refurbishment

When your system needs a more thorough repair and/or cleaning, let us bring your gage into our shop. Our in-house repair team can go in-depth to refurbish, verify, and calibrate your gage to like-new operation.

EMI Gage specializes in refurbishing instruments, especially legacy gages. We revitalize traverse units, control modules, and spindles for surface texture and roundness instruments. We repair surface texture pickups for Talysurf™ models 10, MK1, LASER S5, inductive, Surtronic, and PGI.* We also offer refurbished pickups for purchase or exchange.

We’ll even find a match for an older computer running legacy operating systems, as well as providing standard and custom styli and probes.

Most important, we warranty parts and labor for our repairs and refurbished instruments, so you can be confident that they’ll continue to provide accurate data for years to come.

Check out our current stock of refurbished instruments as well.

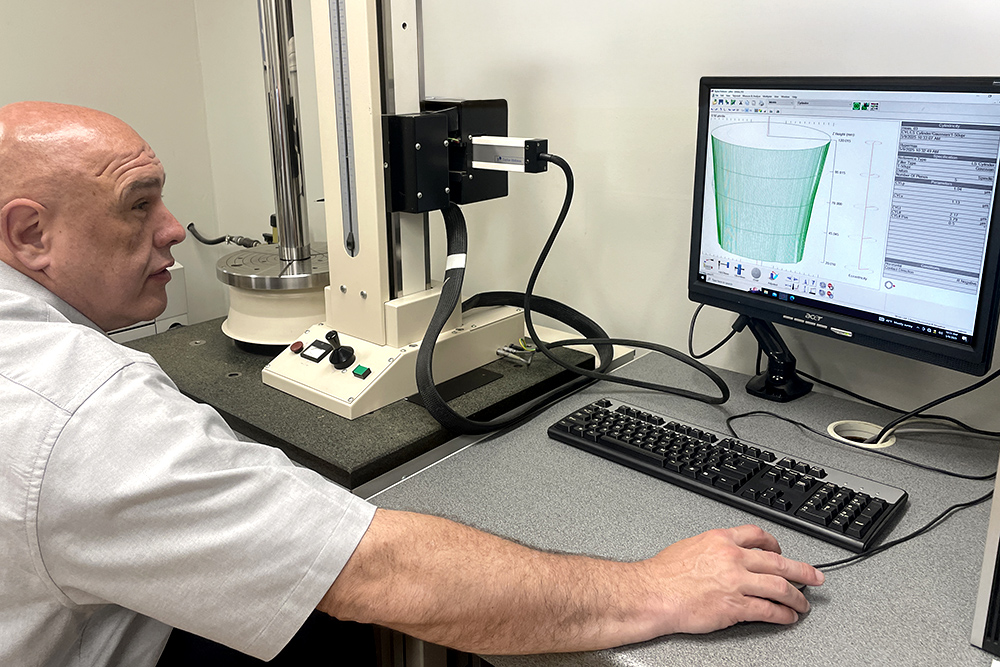

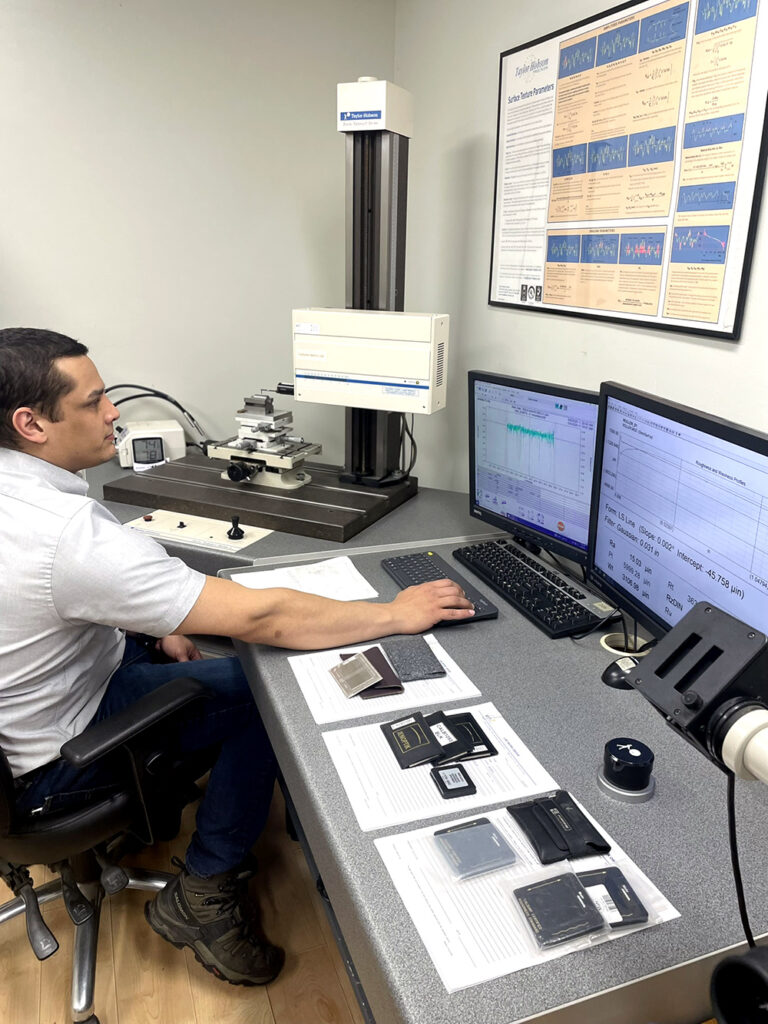

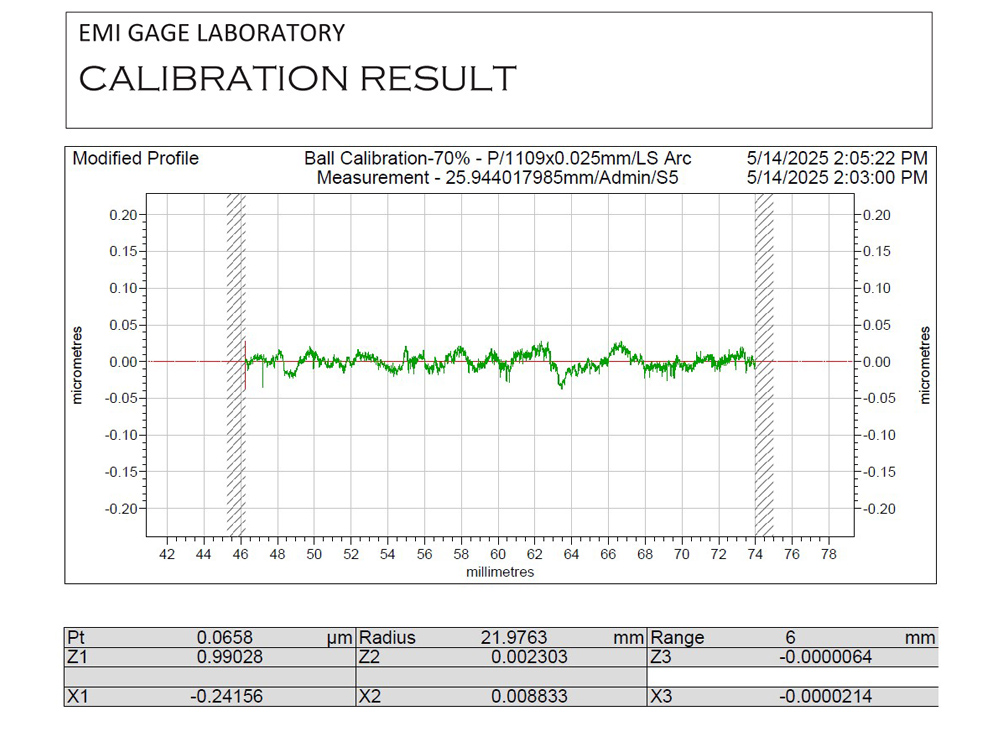

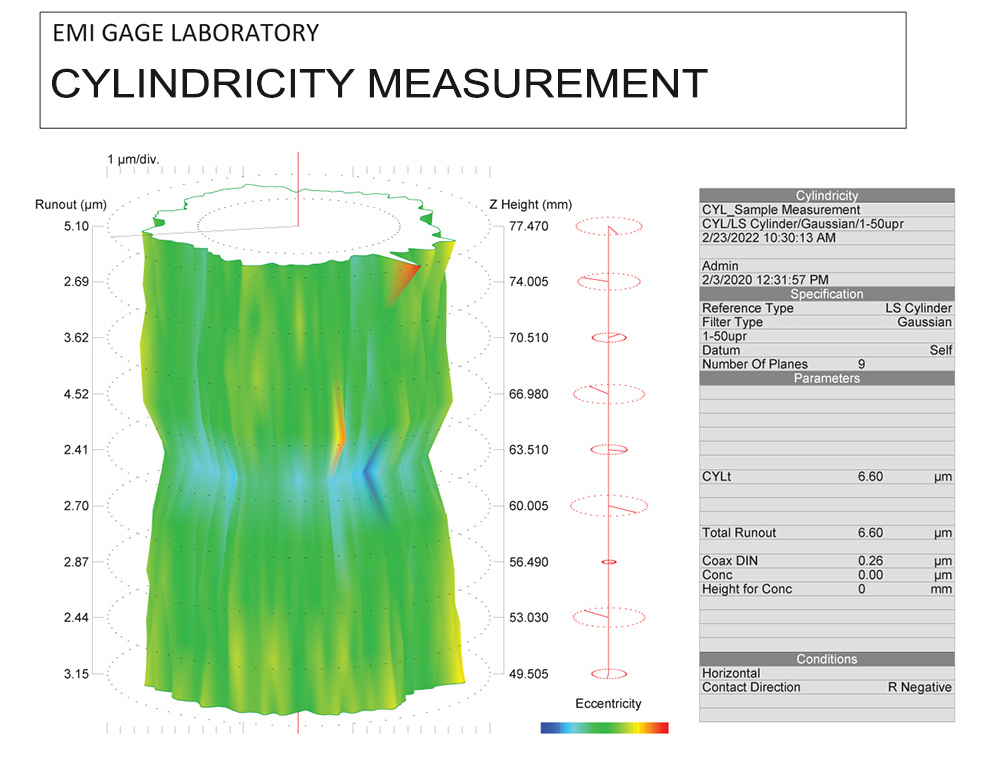

Standards Calibration

EMI Gage calibrates roughness and roundness standards in accordance with ISO and ASME industry standards.

- Roughness standards for Ra (roughness average). We include Rz (maximum peak-to-valley height within a sampling length), a widely used parameter in precision manufacturing.

- Roundness standards (Flick for gage gain setting, and hemisphere/ ball for spindle accuracy).

- Other artifacts for surface texture, form and roundness, all manufacturers. Our 17025 certified lab partners can calibrate additional artifacts.

Computer Replacement

Most “obsolete” gages make fine measurements…they are often only obsolete because of computer and software compatability issues. EMI Gage will help you get the most of your metrology investments by replacing or upgrading the computer, at a tiny fraction of the cost of replacing the entire gage. We supply reliable computers running operating systems from DOS through WIN 10, to keep your gage in service for years to come.

“Obsolete” is not part of our vocabulary!