What does “included angle” mean for a stylus tip?

The term “included angle” can be confusing as it’s come to have two meanings for diamond stylus tips.

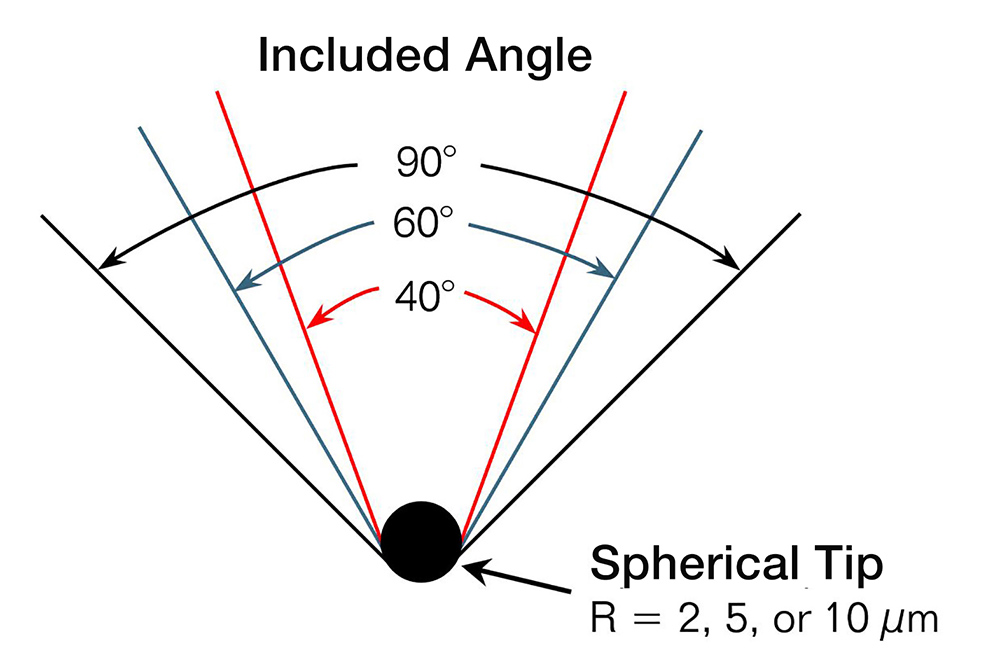

Included angle = Included flank angle = cone angle

In the ASME B46.1 standard, “included angle” is used as a synonym for “included flank angle,” the angle formed by the two sides of the diamond tip. It’s also referred to as the “cone angle” or “conic angle.” This angle, and the radius of the tip, determine the features and slopes that the tip can measure.

Per the ASME B46.1 standard, the included angle is equal to the included flank angle of the diamond tip. Courtesy the Surface Texture Answer Book

Diamond tips with 90° and 60° cone/included angles are the most widely used. They are relatively durable and can accommodate the majority of surface texture and form features. A tip with smaller cone/included angle (as small as 30°) can measure narrower valleys and steeper slopes but is more susceptible to damage.

Measurable arc

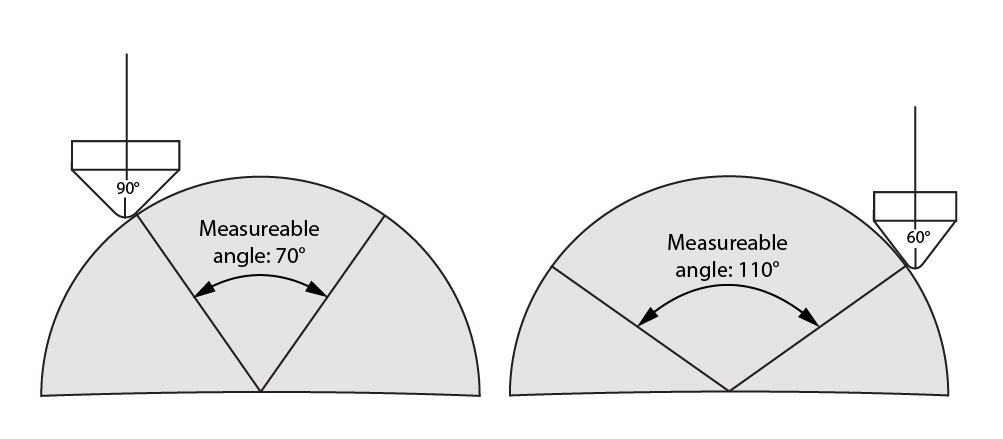

“Included angle” can also define the amount of arc that can be measured with a given stylus. An arc measurement is only valid when the radiused portion of the tip is contacting the surface. At higher slopes, the flank of the tip contacts the surface instead, and the measurement is not valid.

Included angle can also refer to the amount of a spherical ball that can be measured before the stylus flank contacts the surface.

Per the diagram above, a 90° conical diamond tip can measure a 70° included angle (35° degrees either side of the apex). A 60 degree conical tip can measure a 110° included angle. These are the absolute limits of what can be measured without flanking, but bearing in mind the texture of the part, deviation from the spherical shape, and the typical ±5° tolerance on the cone angle, to be safe, the true measurable angle will be somewhat smaller.

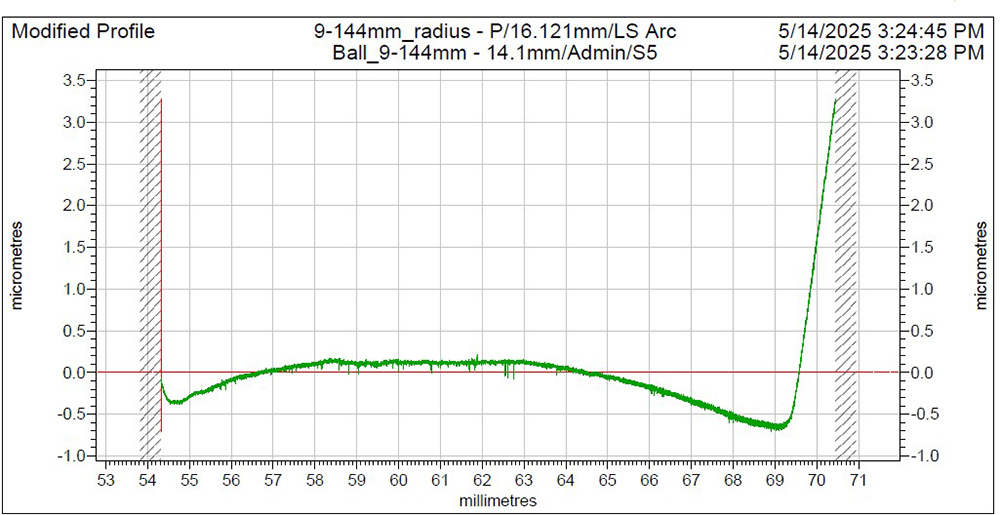

The example trace below shows the primary profile, fit to a least squares arc. Flanking at either end of the measurement resulted in spikes in the profile. The spike is greater at the right end of the trace as more data was acquired right of center.

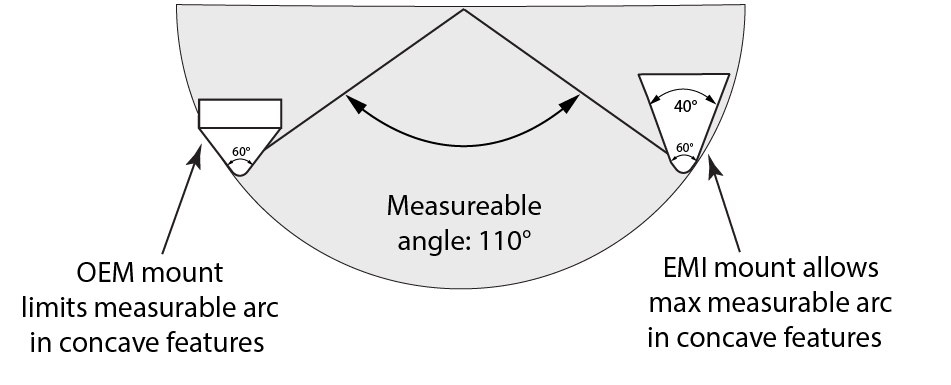

The included angle is similar for convex arc measurements (for example, a bearing race). However, for concave measurements on smaller radii, some OEM mounts can interfere and limit the measureable arc. EMI Gage mounts are based on a 40° angle so that you can measure the maximum arc.

The included angle for a concave surface is the same as for a convex surface. EMI Gage mounts are designed to not interfere with these measurements.

Which tip do you need to measure your particular features? The Included angle is certainly part of the answer, but there are many other factors as well. Contact us about your measurement needs—our experts can help you choose the correct tip, at the best price, for your application.