Measurement Lab Services

The EMI Gage measurement lab provides parts inspection, calibration for artifacts and standards, and measurements for process verification. Our laboratory has been ISO/IEC 17025:2017 certified for over 25 years. We are centrally located in Lake Barrington, Illinois to provide fast turnaround and reliable data to help you dial in your processes.

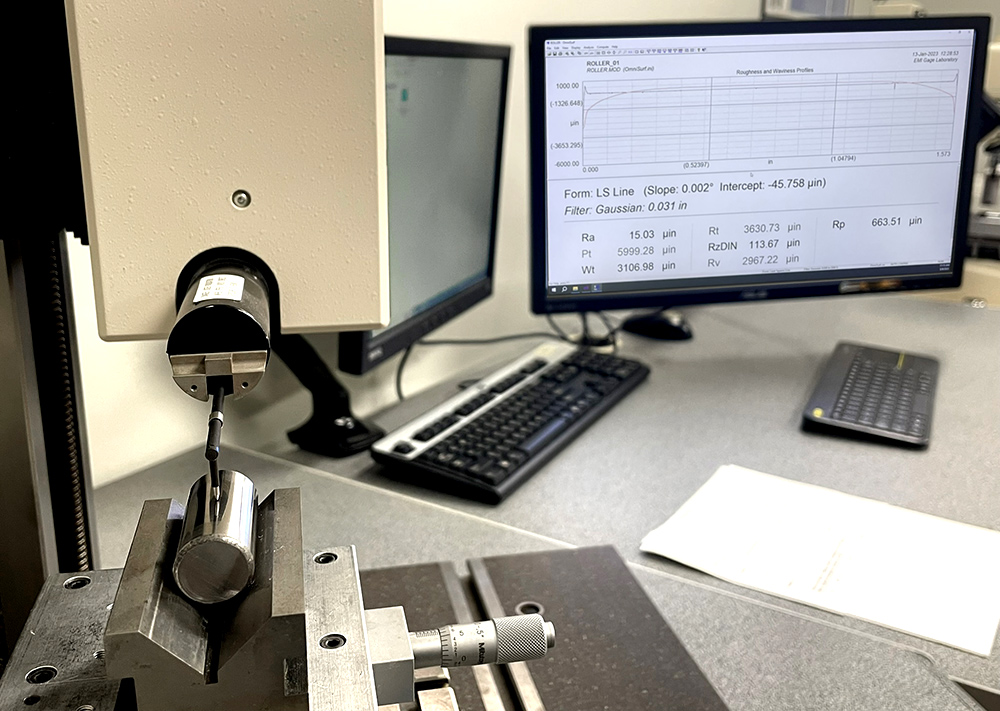

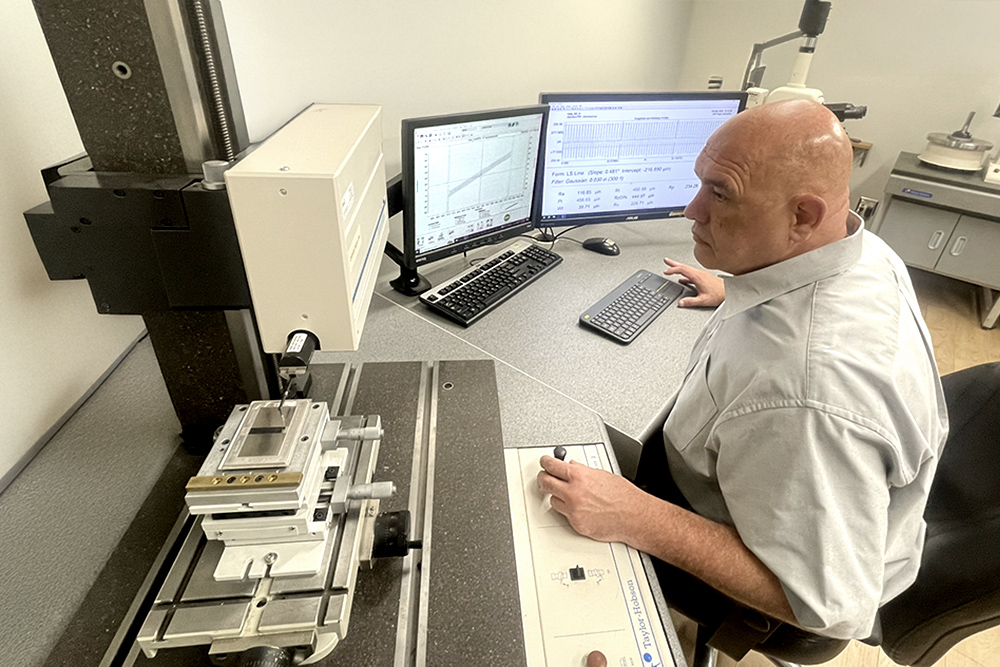

EMI Gage has extensive experience in measuring surface texture, form (profile measurement), and roundness (roundness, straightness, cylindricity, runout, harmonics, parallelism, etc.). Our lab focuses on contact profilometry, which ensures traceable, trustworthy data.

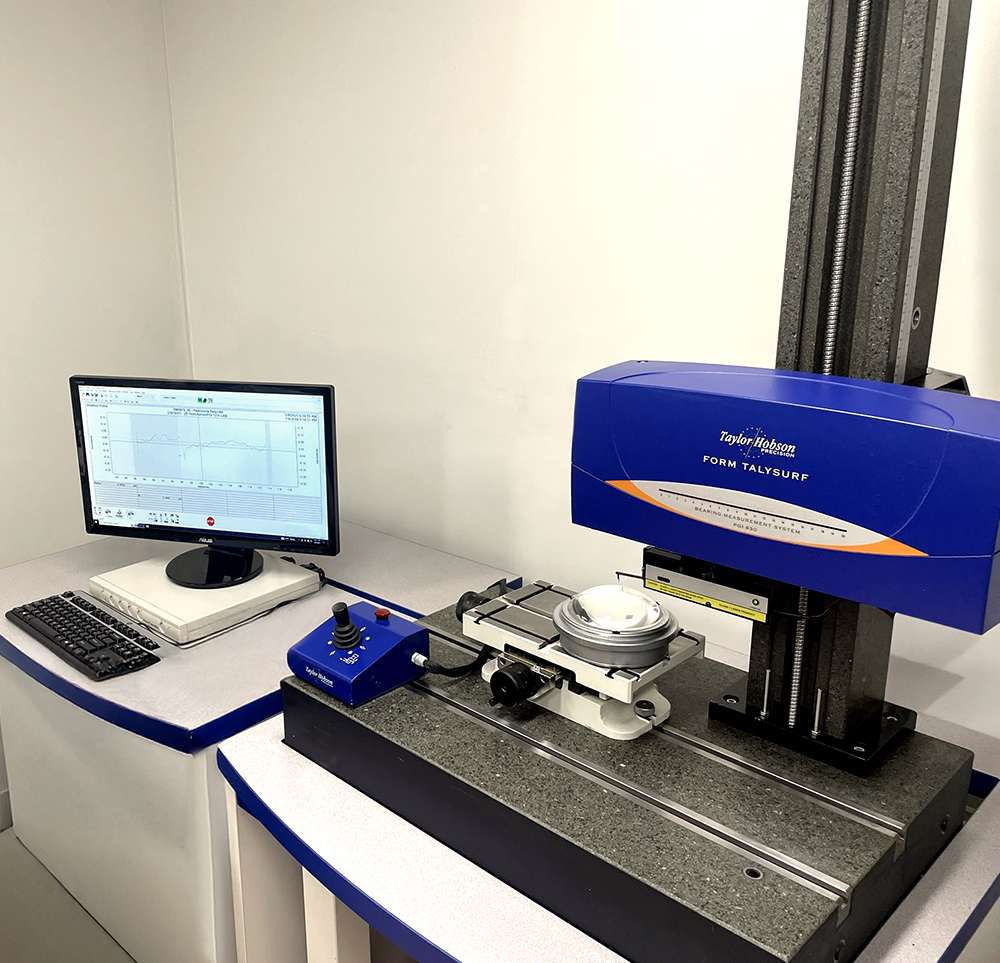

The lab features renowned Taylor Hobson surface texture, form, and roundness measuring systems, as well as many standards, fixtures, and staging equipment for calibration and measurement.

Measurement Capabilities

- Surface Roughness

- Waviness

- Form

- Radius

- Angles

- Squareness and Flatness

- Straightness

- Parallelism

- Step Height and Thickness

- Bearing Ratio

- Wavelength Content

- Roundness

- Runout

- Concentricity

- Cylindricity

- Harmonics

Parts Inspection

EMI Gage’s lab has measured thousands of parts to address correlation issues, solve process or print discrepancies, qualify machine tools for production, and ensure quality up and down the supply chain. We offer fast turnaround on surface roughness, form, roundness, and cylindricity inspection.

Whether you need to measure a few parts or a few hundred, contact our measurement lab to get the data, and answers, you need.

Having issues with a measurement or measurement instrument? We offer consulting services to help you verify your instruments and develop protocols for reliable roundness and surface texture inspection.

Process Verification

When you have new measurement requirements or equipment, our lab staff can measure parts to help you verify your surface texture, form, and roundness measurement procedures and instruments. We give you peace of mind that your measurement results are reliable and adhere to all pertinent standards.

Corellation

Measurements don’t always agree—sometimes between customers and vendors, or between facilities, or even over time. EMI Gage can provide the independent, third party certification you need to resolve discrepancies and determine how to minimize or eliminate differences in measurement results.

ISO/IEC17025:2017 Accreditation

EMI Gage is ISO/IEC17025:2017 accredited and conforms to ISO/IEC 17025 standard practices.

Laboratory Instrument List

EMI Gage maintains a comprehensive set of lab equipment to calibrate surface texture, form, contour, and roundness. Our lab equipment includes:*

The heart of our laboratory is the Liebert Challenger 3000 climate control unit, which maintains temperature at 68º F ± 0.5° F, and humidity at 30% relative humidity (RH). A large HEPA filter array can hold the lab cleanliness to better than Class 10,000.

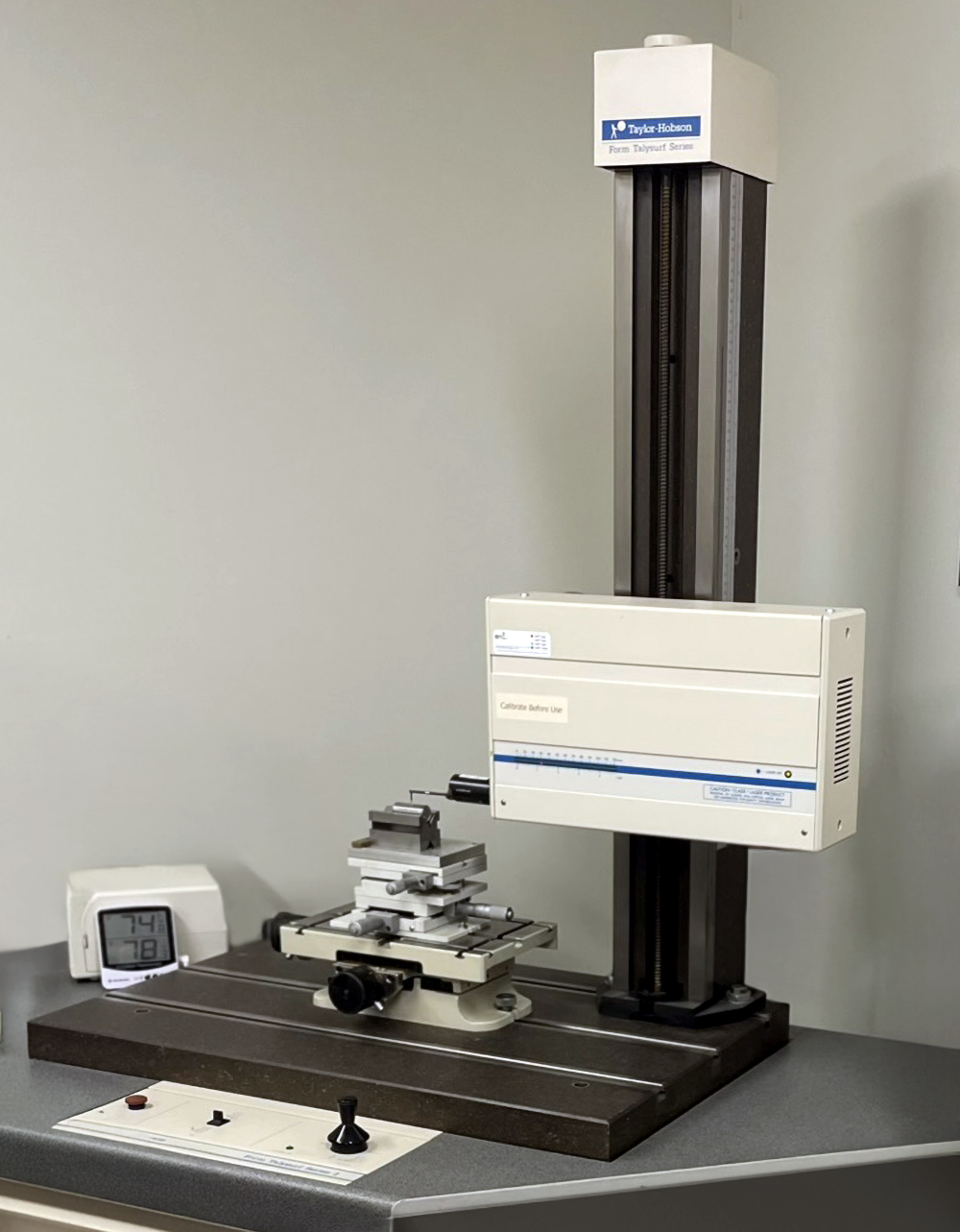

Taylor Hobson Form Talysurf PGI 1230 LASER

Surface Texture, Form, Contour

Max. Measurement Length: 200mm

Column Height: 700mm

Range to Resolution:

– 0.8nm at 12mm Range (0.031µin at 0.47” range)

X-Axis Straightness:

– 0.5mm (20µin) over 200mm (7.87”)

Stylus Motion: Arcuate

Phase Grating Interferometric Transducer

Helium/Neon LASER, 632.8nm wavelength

Taylor Hobson Form Talysurf LASER S5

Surface Texture, Form, Contour

Max Measurement Length: 120mm

Column Height: 700mm

Range to Resolution:

– 10nm at 6mm range (0.39µin at 0.23” range)

X-Axis Straightness:

– 0.5µm (20µin) over 120mm (4.72”)

Stylus Motion: Arcuate

LASER Interferometric Transducer

Helium/Neon LASER, 632.8nm wavelength

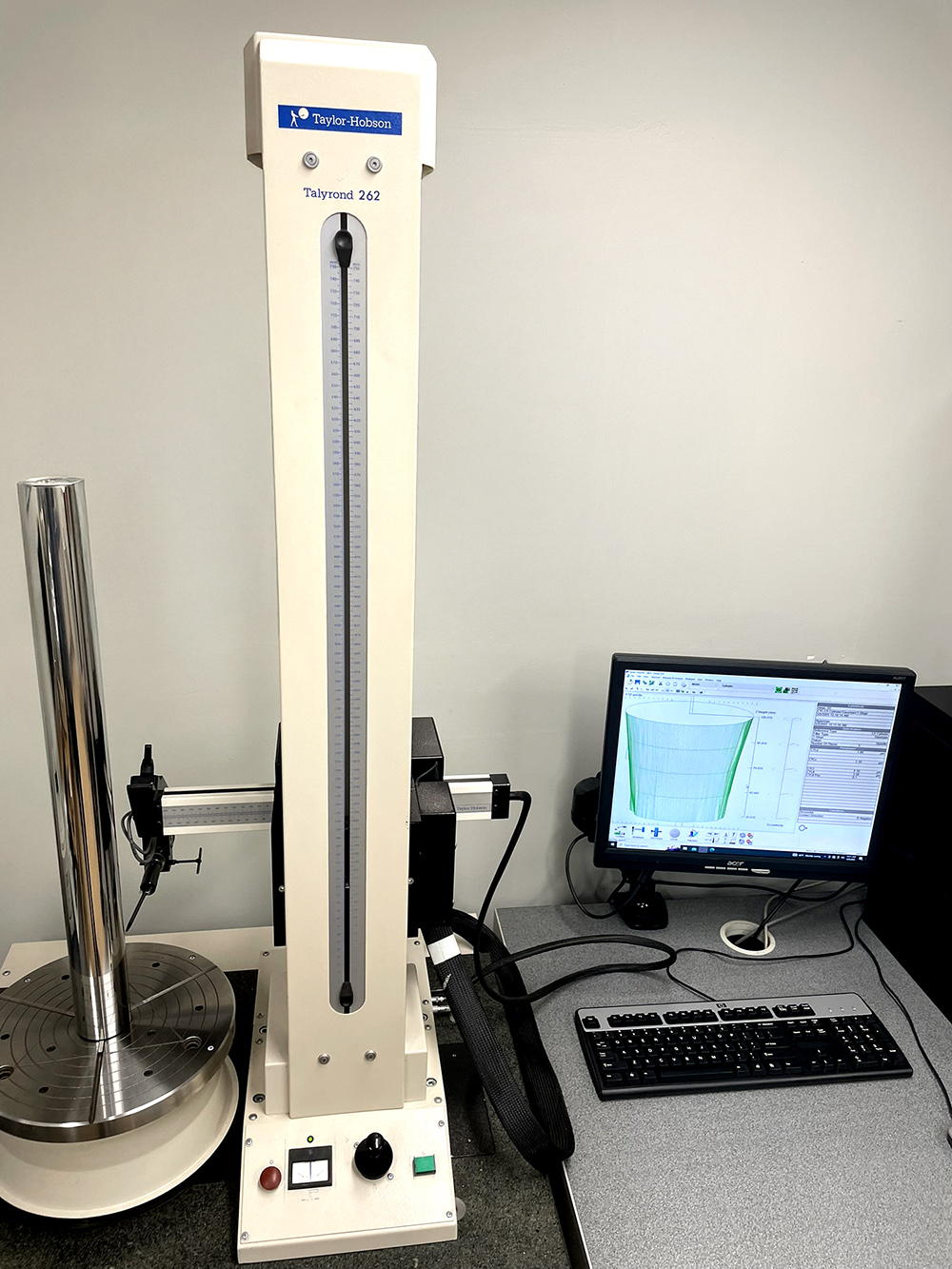

Taylor Hobson Talyrond 262

Roundness

Max. Diameter: 350mm (13.8”), optionally extendable to (500mm (19.7”)

Max. Weight: 50kg (110 lbs)

Max. Height: 750mm

Range to Resolution:

– Normal ±1mm (±0.039”) Resolution 0.060µm (2.36µin)

– High ±0.2mm (±0.0079”) Resolution 0.012µm (0.47µin)

Roundness Limit of Error:

– with 50upr filter: ±(0.04µm + 0.0003µm/mm)

Axial Limit of Error:

– with 50upr filter 0.06µm total

Straightness Limit of Error:

– 2µm over 750mm (78µin over 29.5”)

Parallelism to Spindle Axis:

– 7µm over 750mm (275µin over 29.5”)

Radial Straightness Accuracy:

– 0.5µm over 200mm (with 8.0mm cutoff low pass filter)

– 0.25µm over any 50mm length

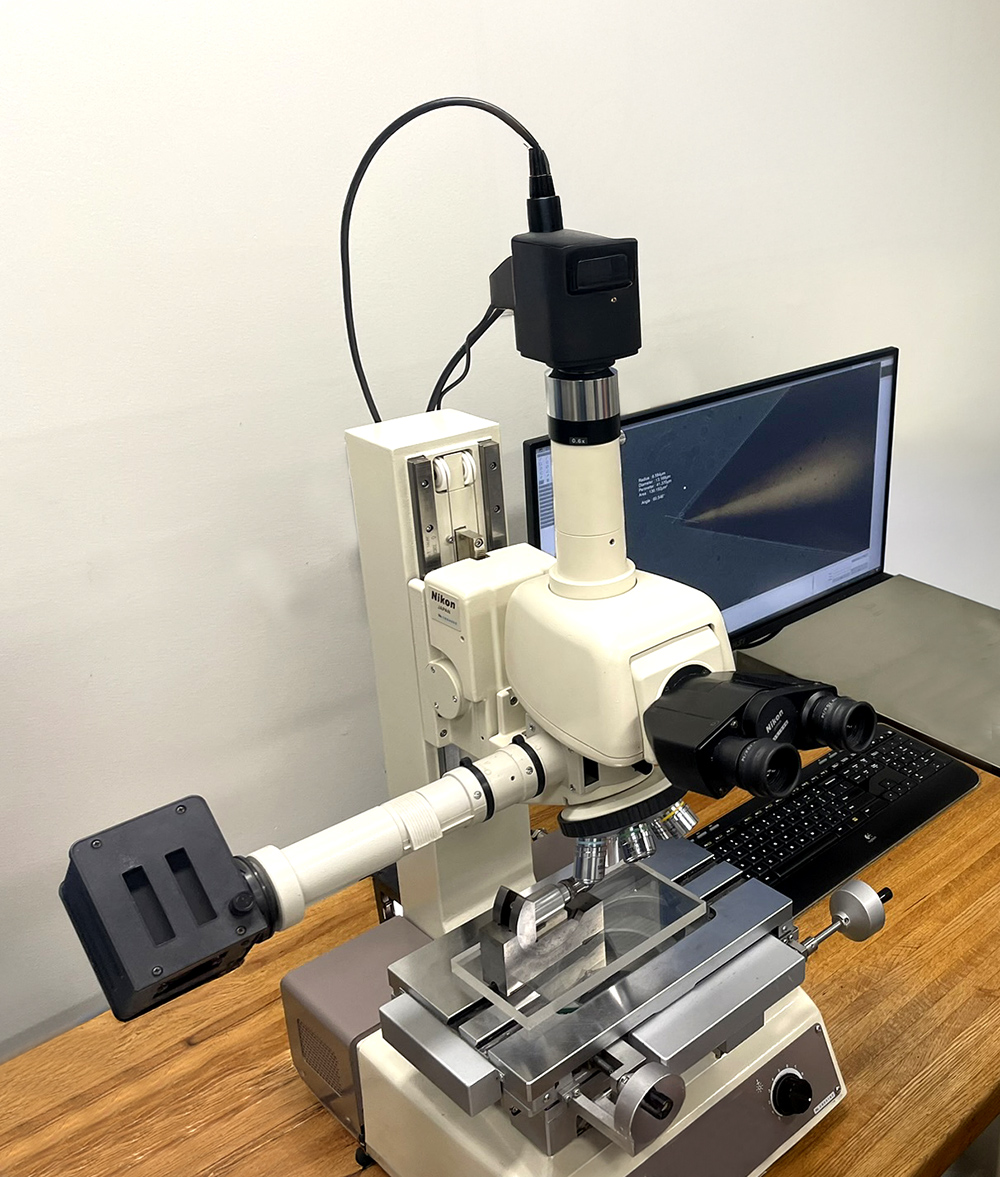

Nikon MM-40 Measuring Microscope

Digital Imaging

Compound microscope, trinocular

Nikon V12-A Profile Projector/Comparator

Liebert Challenger 3000

The Liebert Challenger 3000 climate control unit maintains temperature at 68º F ± 0.5° F, and humidity at 30% relative humidity (RH). A large HEPA filter array can hold lab cleanliness to better than Class 10,000.

Gages and Fixturing

Newport Linear/Rotary Stages

Numerous standards and fixtures amassed over 30 years of operation.